Roll Shop Technology

Rollshop Technology

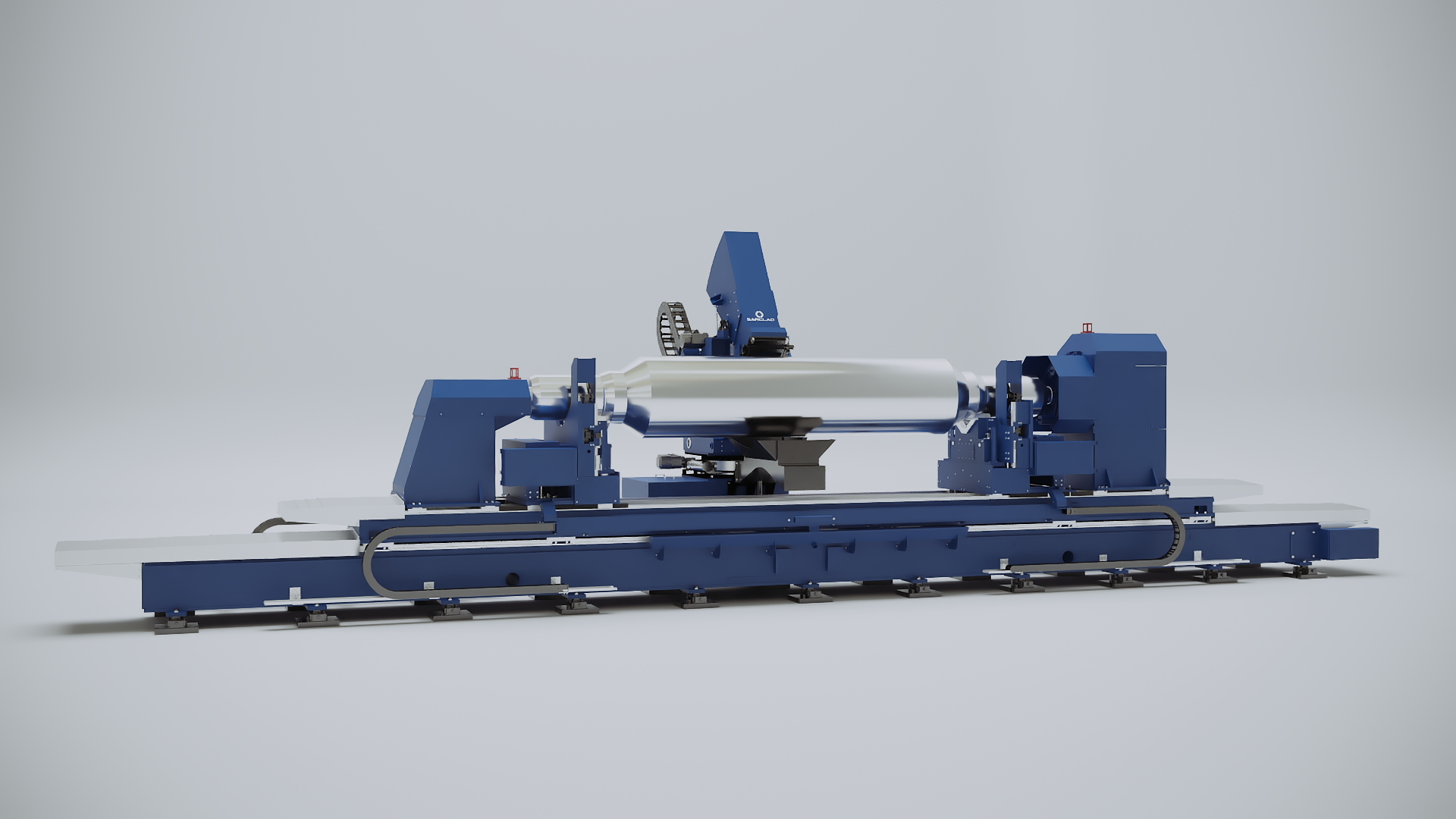

Rolltex, our high-performance EDT Roll Texturing machine, and Rollscan, our proven roll inspection unit, are designed to meet and exceed your needs. We promise to supply the highest level of support to ensure production to suit your texturising and inspection requirements. Leading the industry with developing technology to keep rolls optimally textured and defect free is what sets us apart from other suppliers.

Sarclad offers multiple Rolltex EDT Roll Texture machines to cater to our customers diverse roll texturing requirements. Our team is here to help you find the right fit for your needs. Rolltex EDT versions include MSA (Multi Servo Array), MRV (Moving Roll Variant), MSV (Moving Saddle Variant) and ECO, all focused on quality results based on different capacities.

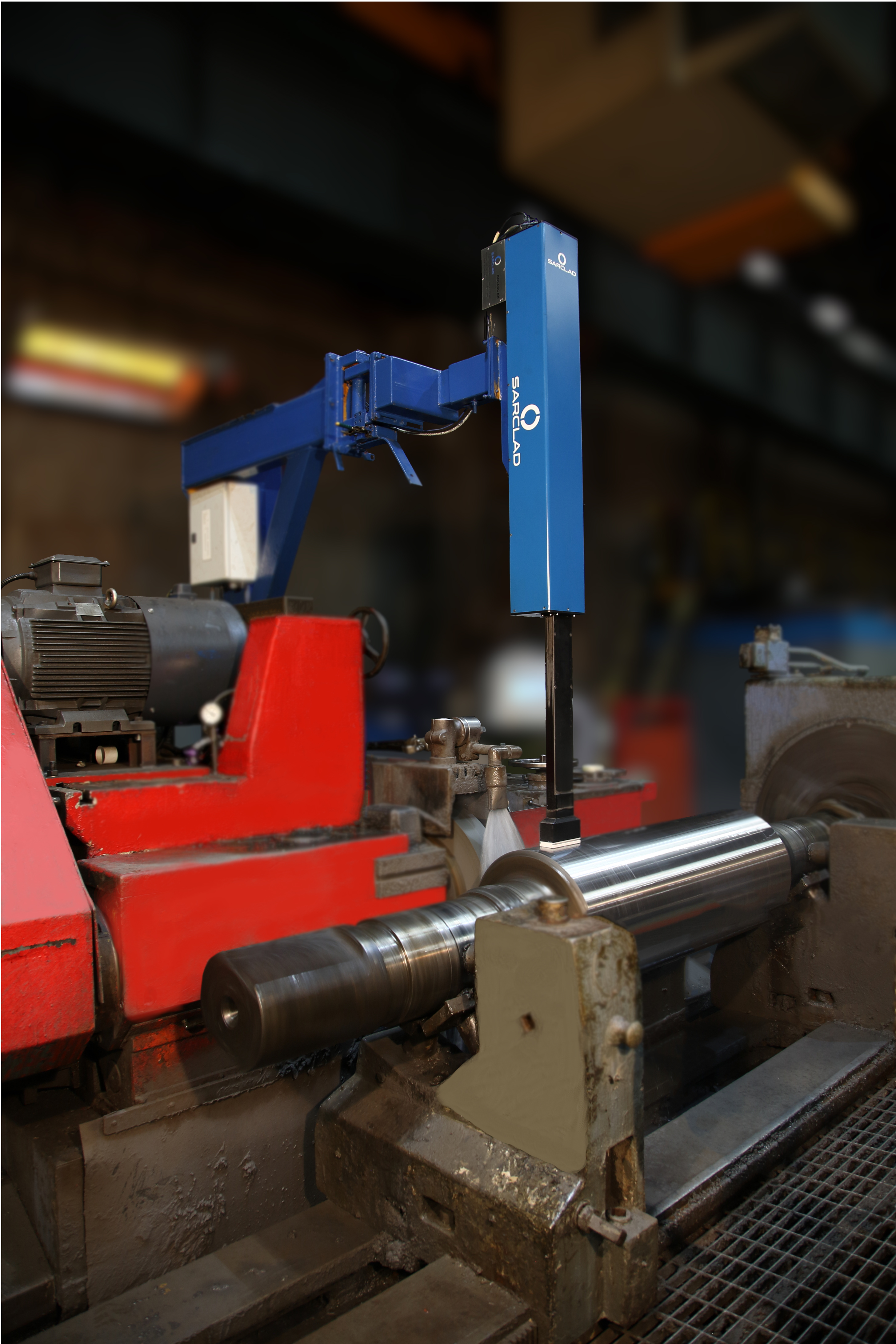

Sarclad also offers the latest technology for roll inspection, enabling you to keep your roll fleet in defect free and safe condition. For customers only concerned with surface defects, the eddy current only Rollscan will be a good match. For customers also wishing to detect issues in the core of the roll or just beneath the surface, two types of ultrasonic technology can also be included on the single probe head. Compression wave ultrasonics detect issues within the core itself such as non-metallic inclusions, whilst surface wave technology can also be included to find any defects just below the surface.