Sarclad's EDT Roll Texturing

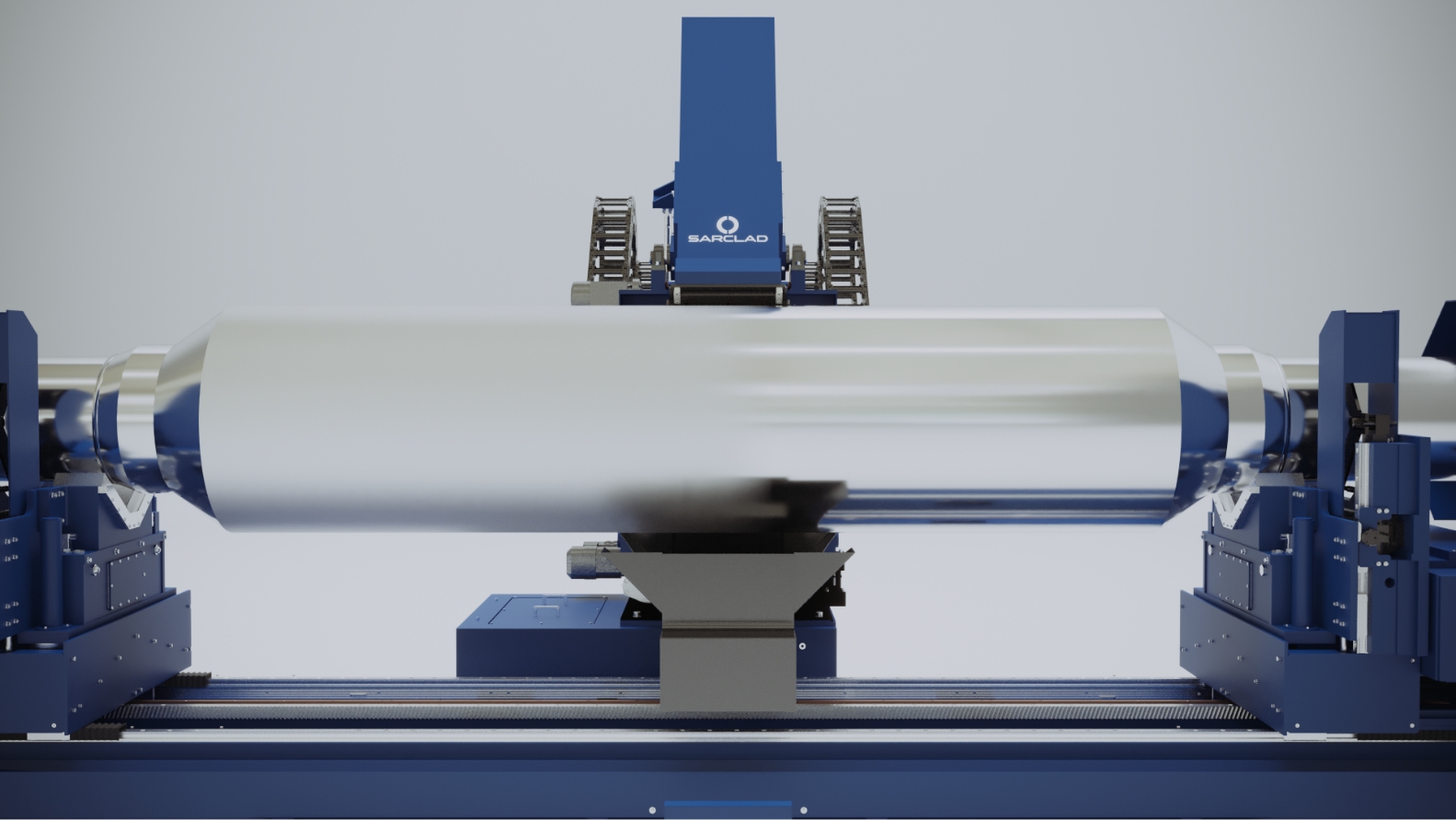

Sarclad is the world leader in EDT (Electro Discharge Texturing) machines, delivering unrivalled surface texture control of your work rolls and strip products.

Quality demands on textured steel sheet are growing at an ever-increasing rate. Automotive customers are placing tighter demands on steel producers due to pressure to reduce thickness of coating and painting layers, all the time requiring the best forming behaviour and visual appearance after coating and painting. Textured work rolls of the highest surface quality are essential to meeting these demands.

Sarclad has delivered more than 120 Rolltex roll texturing machines based on Electrical Discharge Texturing (EDT) technology since 1987. EDT replaced shot blast texturing technology (SBT) due to tighter surface tolerance and repeatability, and continues to be the de facto standard for surface-critical applications. Various alternative technologies have tried and failed to gain traction.

Laser and electron beam-based texturing technologies produce repeating patterns and micro-features in the roll surface that prevent the sheet being acceptable for use in exposed automotive applications. Roll processing times are dramatically slower than EDT. Furthermore, consumption of inert gas during the texturing process is wasteful and costly.

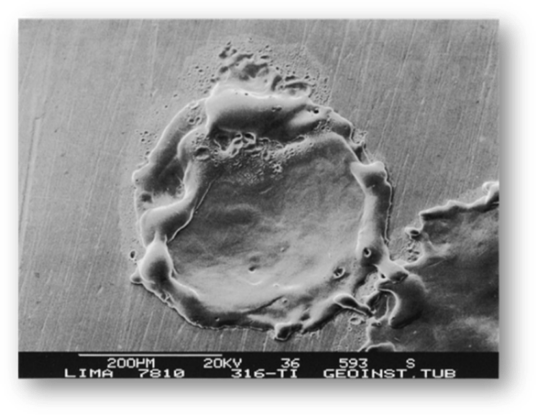

EDT naturally produces complete coverage of the roll surface. Each electrical discharge produces a microscopic crater which acts to concentrate the electrical field density, such that the next discharge produces an adjacent crater. This effect creates consistent and repeatable surface texture with no directionality. It is this stochastic, isotropic surface which is so highly prized by automotive OEMs and others that require the highest quality sheet.

Sarclad’s EDT machines ensure precise delivery and control of the key surface parameters for each customer, namely Roughness (Ra), Peak count (Pc) and Skew (Rsk). These settings can easily be adjusted on each machine, ensuring for example, that the wide range of surface parameters stipulated by Automotive OEMs, can all be met.

Sarclad’s EDT machines are also the environmental choice for your requirement. Operating VOC free, Sarclad’s machines comply with the strictest global emission requirements. Compared to submerged bath design alternatives, Sarclad machines operate with approximately 90% less oil and utilise re-usable as opposed to disposable fume filters. This in turn helps to ensure lower consumable cost per roll than both submerged batch and laser texturing alternatives.

The decision to invest in a Rolltex EDT machine is an enabler for any steel or aluminium mill. Looking to step up or into the supply of surface critical strip for markets such as automotive, white goods, aerospace and packaging.

Benefits of EDT

-

Full and complete texturing of the roll

-

Unrivalled control of the process variables – current, voltage, spark duration and electrode to roll gap

-

EDT can be sized and scoped to meet your textured roll demand

-

Wide range of texture capability covering Ra 0.5 to 15µm

-

Typically, lower civil and foundation costs versus alternative requiring larger footprints

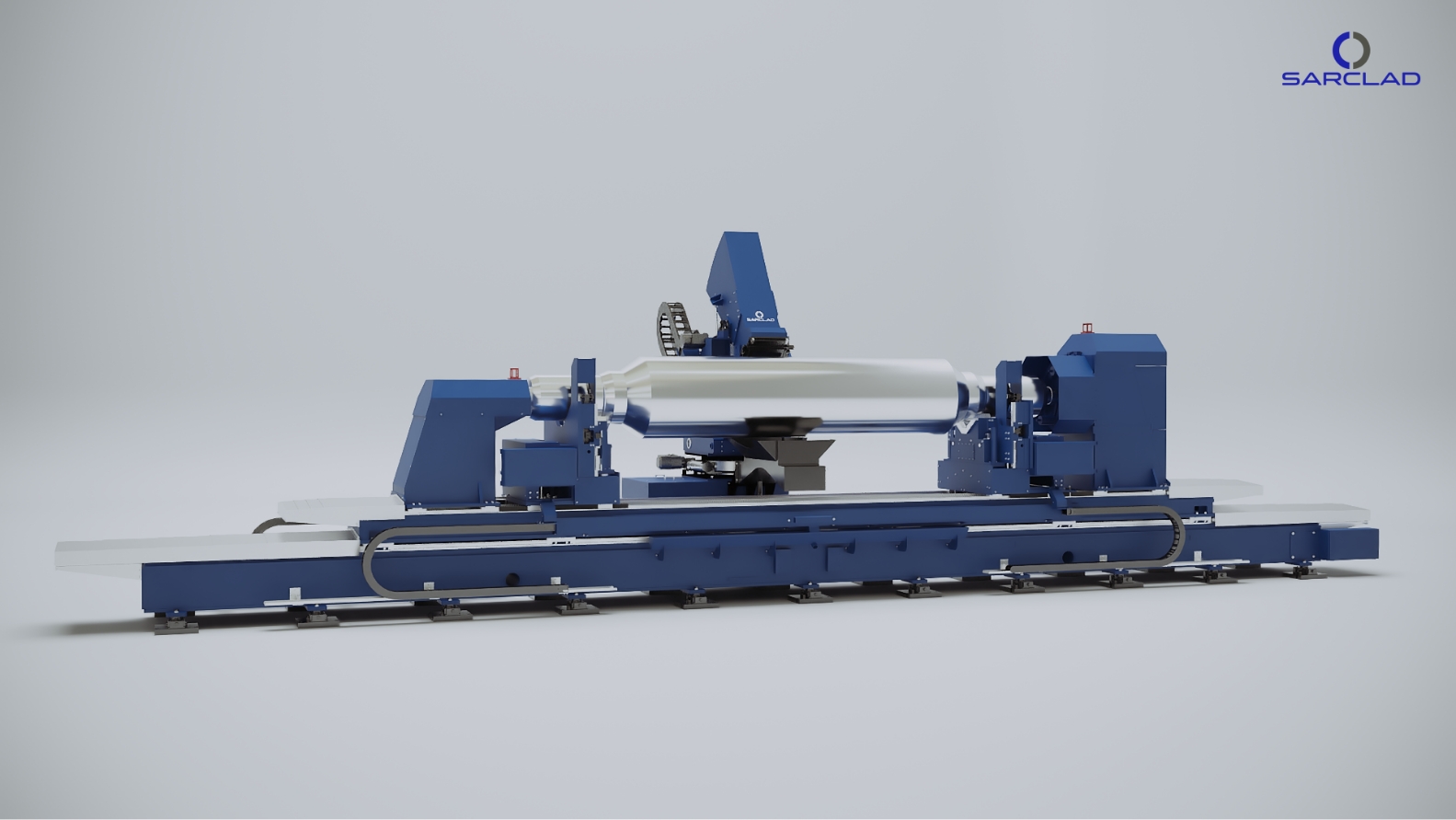

MSA (Multi -Servo Array)

Distinguishing Features

Individual elelectrode control. Texture head array design. Texture head remains static. Roll is traversed to texture head.

Advantages

Unrivalled texture roll control and efficiency across Ra and peak count range. 99% texture efficiency. Grind defect removal. Speed & capacity

Target Segments

Exposed automotive panels. Aerospace. High volume mills

Ra Range (on roll)

0.5 - 12

Roll Diameter Range

200 -850mm

Roll Barrel Length

300 - 2500mm

No. of Electodes

12 24 36 48 72

Capacity (Roll p.a. approx)

3438 5313 6875 8438 10625

Texture time mins : 1650 x 450 @ 2.5 Ra

80 0 38 0 27

Expandable

Yes Yes Yes Yes No

Consumable cost $ per roll

13.6 12.9 12.4 12.0 11.6

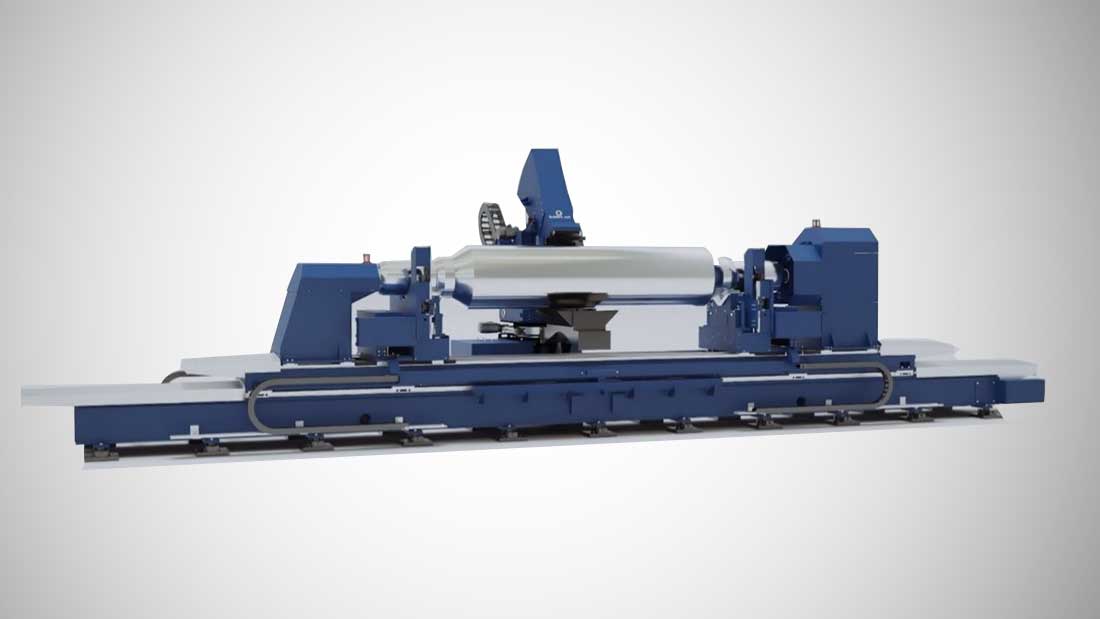

MRV (Moving Roll Variant)

Distinguishing Features

Texture head remains static. Roll traverses to texture head. Electrodes controlled in groups of 12 by single servo

Advantages

Proven reliability for precision control and stability

Target Segments

Strip for wide variety of end markets including Packaging, White goods, Construction and Automotive

Ra Range (on roll)

0.5 - 12

Roll Diameter Range

200 -800mm

Roll Barrel Length

300 - 2500mm

No. of Electodes

12 24 36 48 72

Capacity (Roll p.a. approx)

2750 4250 5500 6750 8500

Texture time mins : 1650 x 450 @ 2.5 Ra

100 48 34

Expandable

Yes Yes Yes Yes No

Consumable cost $ per roll

14.0 13.3 12.8 12.4 12.0

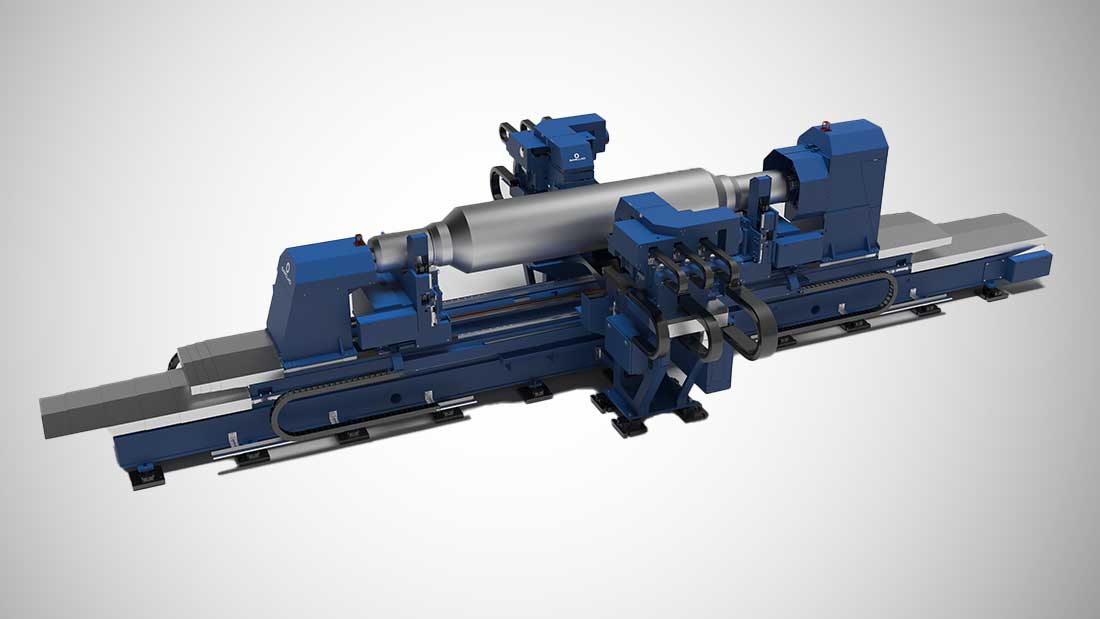

MSV (Moving Saddle Variant)

Distinguishing Features

Roll remains static. Texture head is traversesd from one end of roll to the other. Electrodes controlled in groups of 12 by single servo

Advantages

Can be built on platform with minimum foundations. Requires smaller footprint than MRV

Target Segments

Strip for wide variety of end markets including Packaging, White goods, Construction and Automotive

Ra Range (on roll)

0.5 - 12

Roll Diameter Range

200 -800mm

Roll Barrel Length

500 - 3000mm

No. of Electodes

12 24 36 48 72

Capacity (Roll p.a. approx)

2750 4250 5500 6750 8500

Texture time mins : 1650 x 450 @ 2.5 Ra

100 48 34

Expandable

Yes Yes Yes Yes No

Consumable cost $ per roll

14.0

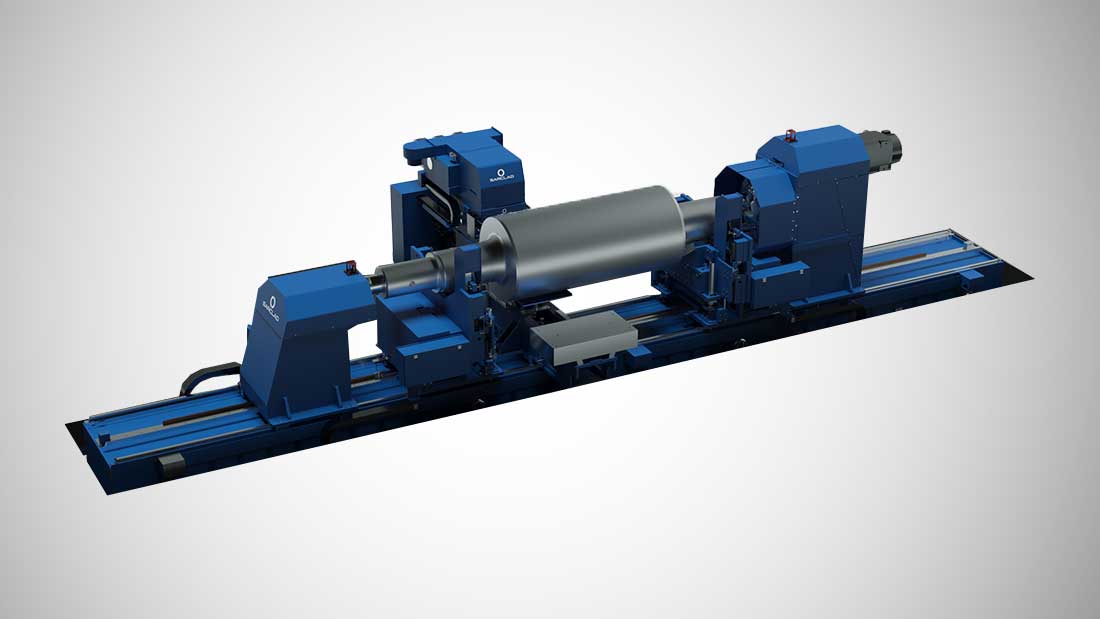

Advantages

High capacity utilisation for low demand applications

Target Segments

Aluminium and low volume steel mills

Ra Range (on roll)

0.5 - 12

Roll Diameter Range

200 -800mm

Roll Barrel Length

500 - 3000mm

No. of Electodes

12

Capacity (Roll p.a. approx)

1000

Texture time mins : 1650 x 450 @ 2.5 Ra

100

Expandable

No

Consumable cost $ per roll

13.6