Jun 28th 2024

Triple EDT Success

Sarclad secures orders from US, Mexico & China

Sarclad is pleased to confirm triple EDT success this quarter, with orders from the United States, Mexico and China. Two of the world’s leading steel suppliers who have now chosen Sarclad’s latest EDT roll texturing technology for their flagship plant expansions includes; Steel Dymanics Inc. (SDI) and ArcelorMittal Nippon Steel (AM/NS).

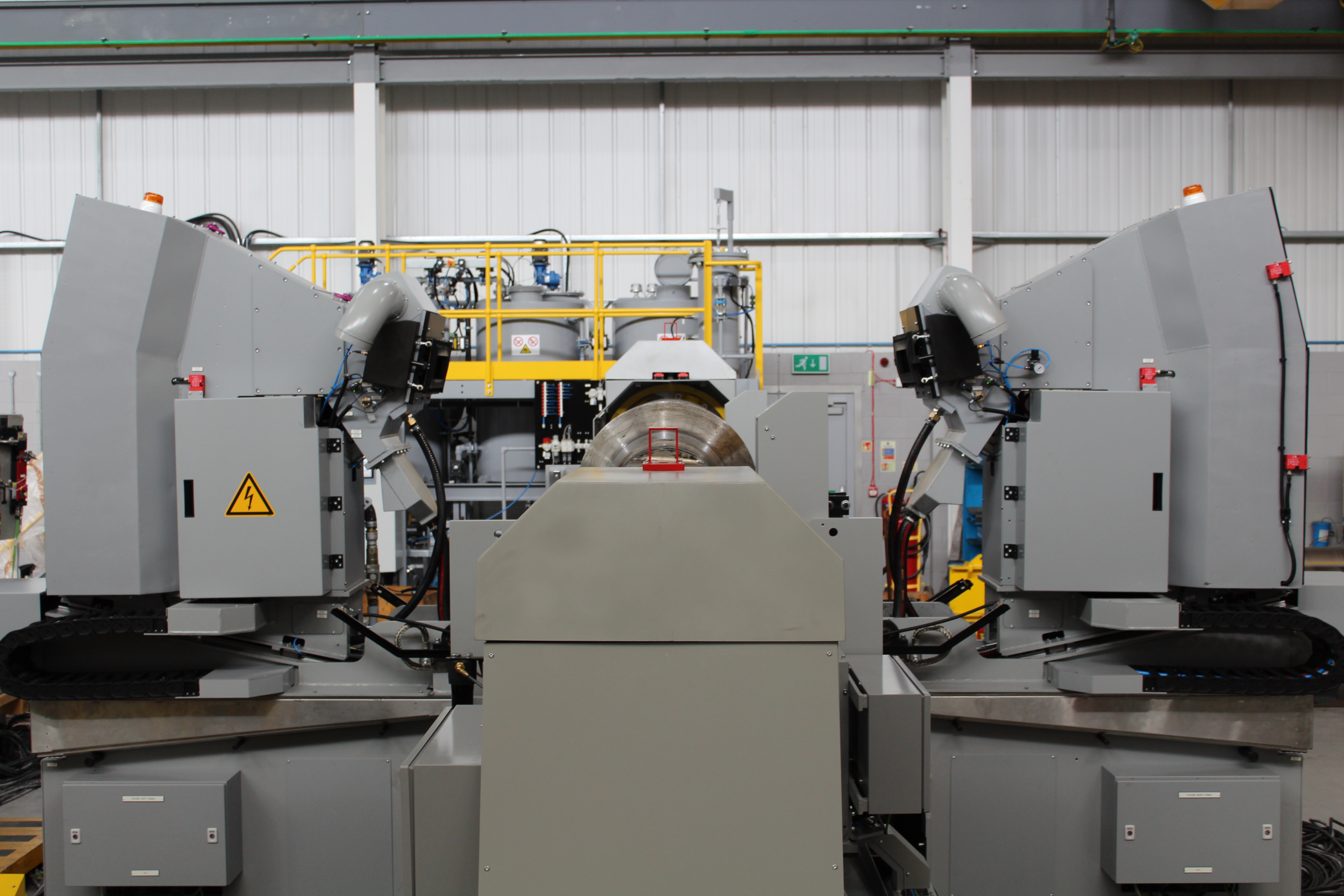

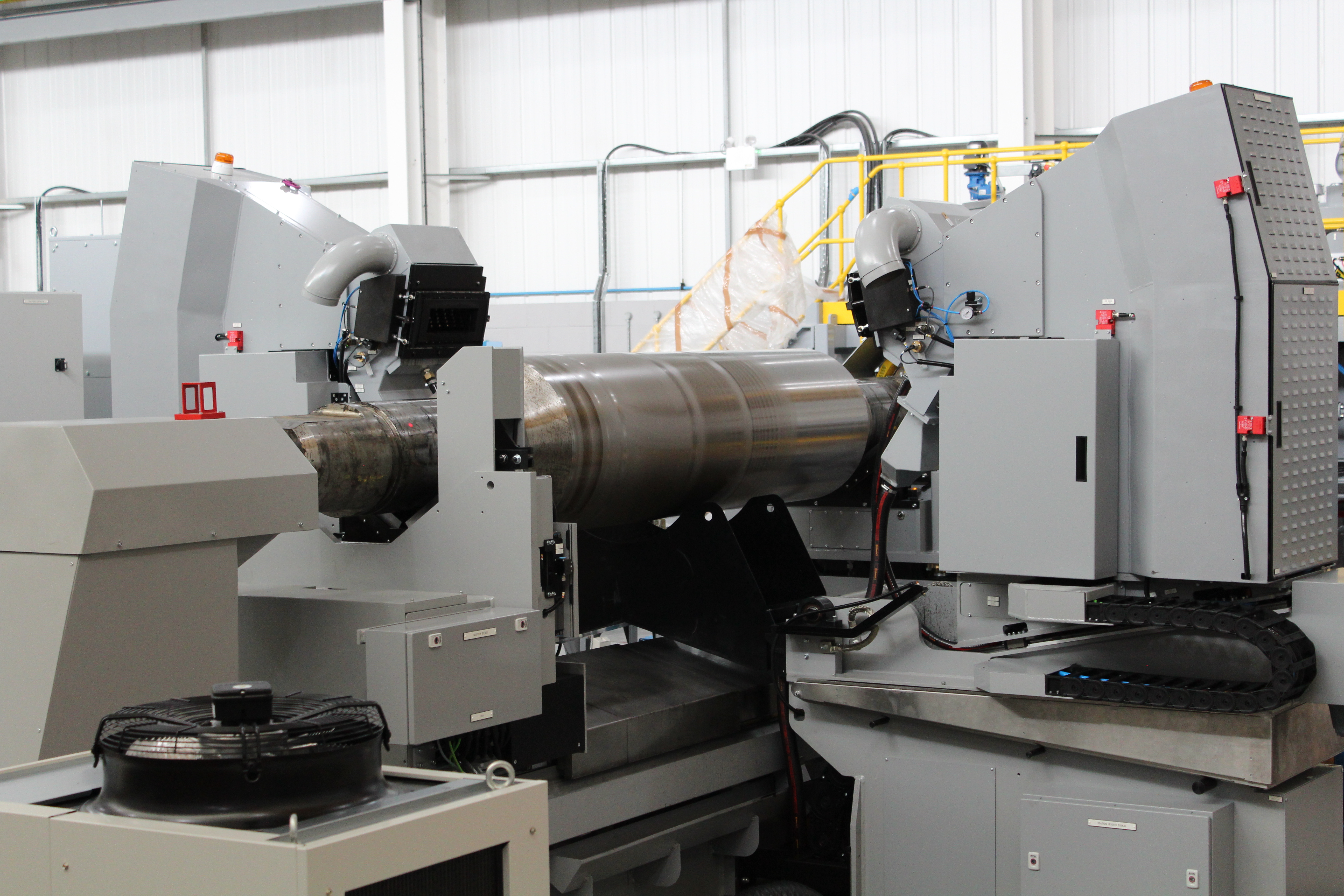

The AM/NS MSA (featured in the photo) is the second MSA system to be delivered and is the first to be specified in the full 72 electrode configuration, for the Cold Mill No.2 expansion in Hazira, India.

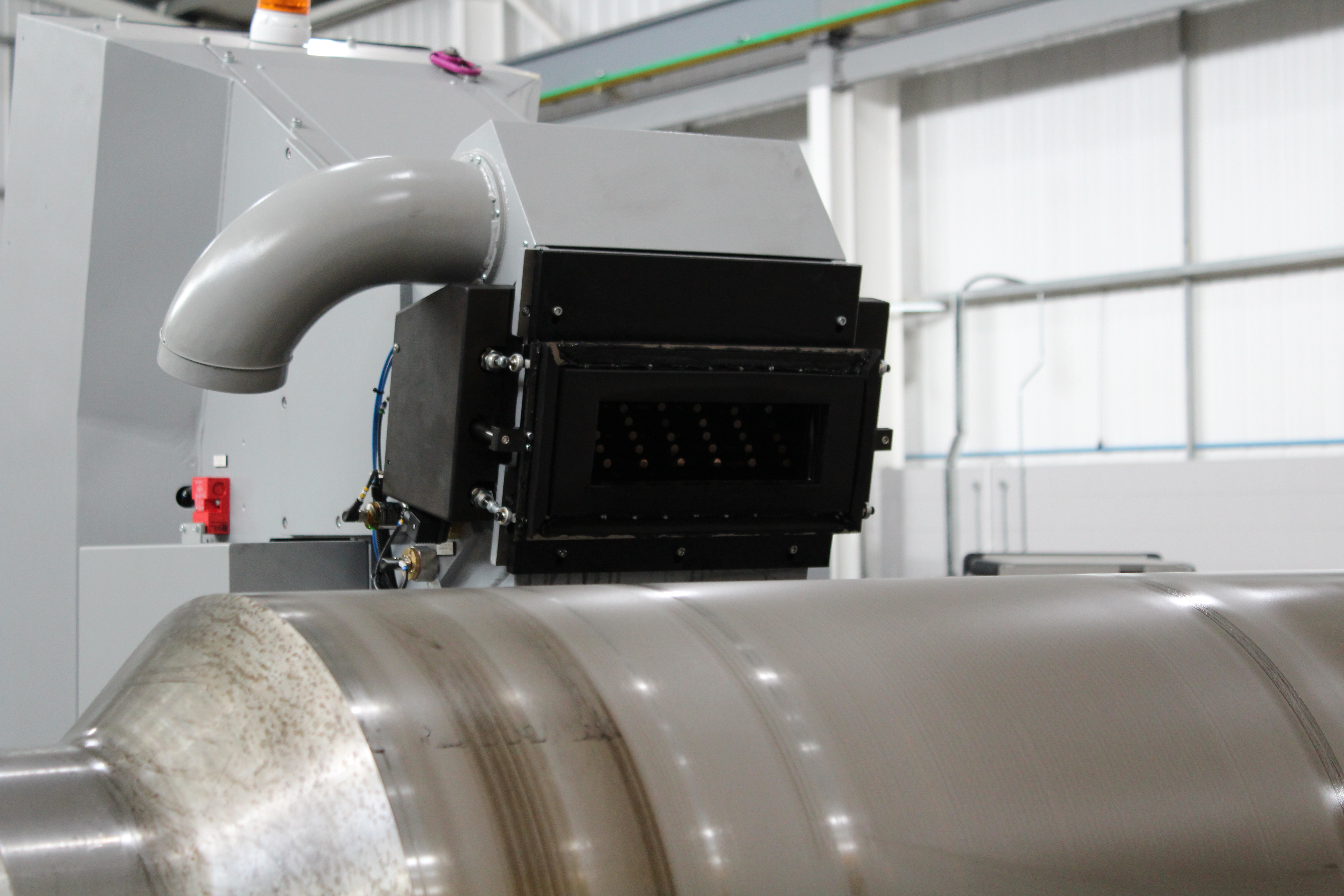

This

state-of-the-art EDT MSA machine features two texture heads as shown in the

photo, each with 36 individually controlled electrodes.

The ground-breaking texturing efficiency generated by MSA technology, enables

unrivalled accuracy, speed and consistency of surface texture on the roll and

ultimately on the strip. Sarclad Rolltex

MSA is the ideal choice for flagship steel and aluminium mill roll shops looking to increase volume and control of

surface-critical strip into applications such as exposed automotive panels.

Steel Dynamics Inc. (SDI) has also selected Sarclad’s Rolltex MSA for their state-of-the-art mill investment in Sinton, Texas. The Rolltex MSA 36 features a single-sided texture head, which can be expanded to 72-electrode capacity by adding a second texture station in the future.

Please contact sales@sarclad.com for more information.